Gas welding, often referred to as oxy-fuel welding (OFW), is a welding process that uses fuel gases and oxygen to generate a high-temperature flame for welding and cutting metal. Here's an overview of the equipment typically used in gas welding:

Gas welding, often referred to as oxy-fuel welding (OFW), is a welding process that uses fuel gases and oxygen to generate a high-temperature flame for welding and cutting metal. Here's an overview of the equipment typically used in gas welding:

Here's how welding heating typically works:

Gas welding equipment requires proper setup, maintenance, and safety precautions to ensure safe and efficient operation. Training and experience are essential for welders to use gas welding equipment effectively and produce high-quality welds.

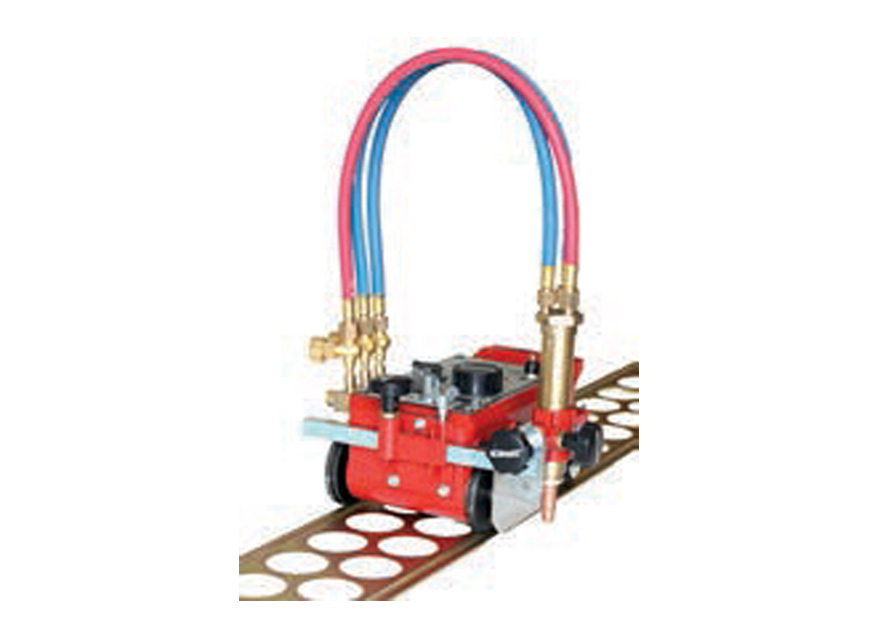

also known as oxy-fuel cutting machines, are used to cut metal plates and sheets using a high-temperature flame generated by the combustion of a fuel gas (such as acetylene, propane, or propylene) and oxygen. These machines are commonly used in metal fabrication, construction, and manufacturing industries.

Here's an overview of the components and operation of gas cutting machines:

Gas cutting machines are versatile tools capable of cutting a wide range of metals, including steel, stainless steel, aluminum, and copper alloys. They are used in various industries for applications such as metal fabrication, shipbuilding, construction, and repair and maintenance. Proper training, maintenance, and safety precautions are essential when operating gas cutting machines to ensure safe and efficient cutting operations.